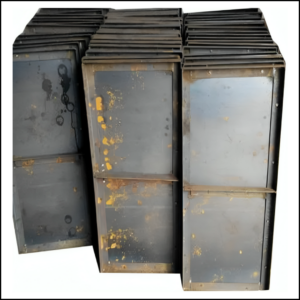

Shuttering Plates

Shuttering plates, also known as centering plates, are essential components in RCC (Reinforced Cement Concrete) construction. Made from high-quality metals, they provide strong and stable support for slabs, canopies, beams, and lintels during the concrete pouring and setting process. Their durability and load-bearing capacity make them a preferred choice over traditional wooden plates.

Compared to wooden alternatives, These plates are stronger, more durable, and reusable, making them a cost-effective option for construction projects. They come in various sizes to accommodate different structural requirements.

The two main types of shuttering plates available are welded and riveted. Welded plates provide enhanced strength and stability, while riveted plates offer flexibility in assembly and dismantling.

Typically, shuttering plates are manufactured using 3.00 mm or 2.5 mm thick mild steel (MS) sheets, reinforced with MS angles of 25×4 mm, 30×5 mm, or 35×5 mm for added strength. These plates can be customized to specific dimensions based on project requirements, ensuring adaptability for various construction applications.

It is play a vital role in modern construction by maintaining the shape and structural integrity of concrete elements. Their high strength, reusability, and resistance to wear and tear make them an indispensable tool in building construction. Proper maintenance and storage of shuttering plates can further extend their lifespan, making them a reliable and cost-efficient solution for multiple construction cycles.

Contact Us for scaffolding rental service.